| Model NO. | GY-SW252 | After-sales Service | Full Drawing, Install Guide or Training |

| Member | Steel Column | Warranty | 30-50 Years Service Life |

| Carbon Structural Steel | Q355 | Type | H-Section Steel |

| Application | Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Frame Part, Steel Walkway and Floor, Steel Structure Bridge, Steel Workshop, Warehouse, Department, Steel Hangars | Standard | ASTM |

| Trademark | Carbon Structural Steel, Ganyo | ||

| Forming | Hot-Rolled Steel | ||

| Material | Steel Structure | ||

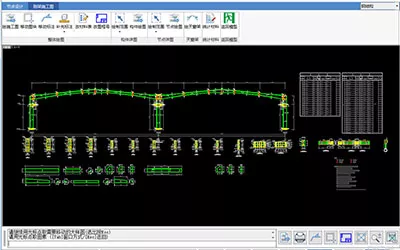

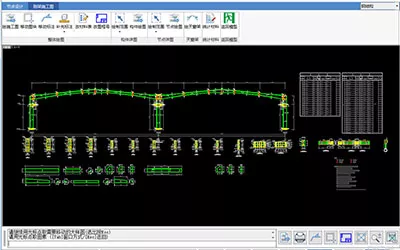

| Structure Frame | Portal Frame | Software We Used | Auto CAD, Pkpm, Tekla |

| Steel Code | Q355 & Q235 | H Steel Type | Hot Rolled H-Beam or Welded H Beam |

| Wind Loading | 80km/H-120km/H, or as Client′s Requirement | Snow Loading | as Per Customer′s Requirements |

| Seismic Grade | 7 Grade | Connection Method | Bolts Connection |

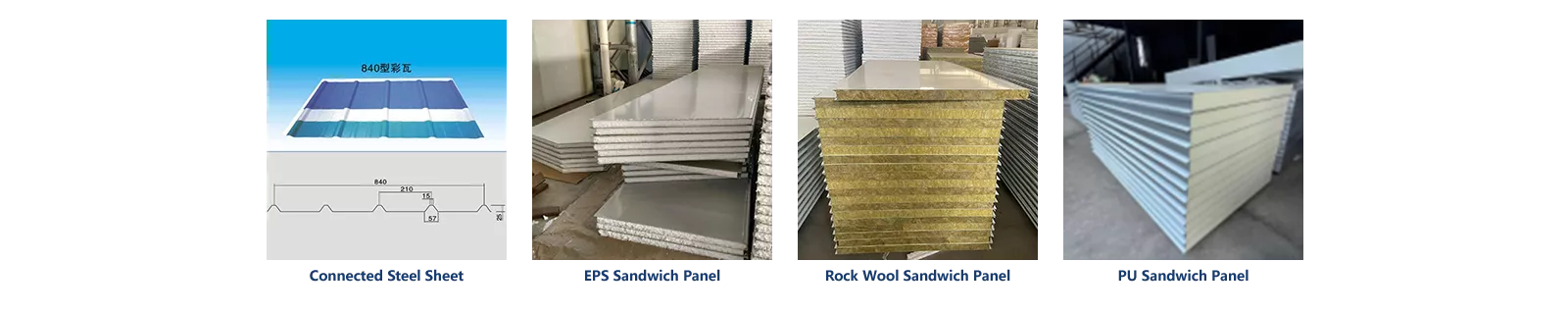

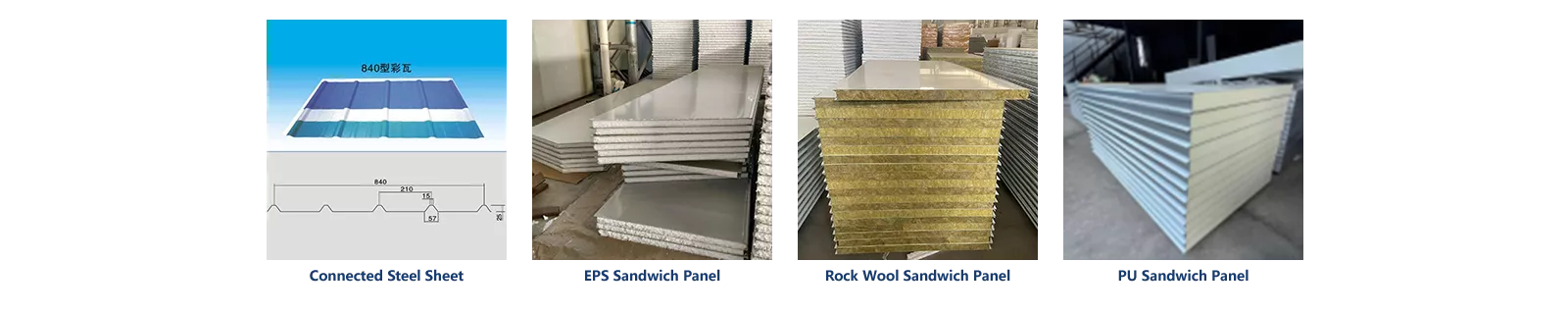

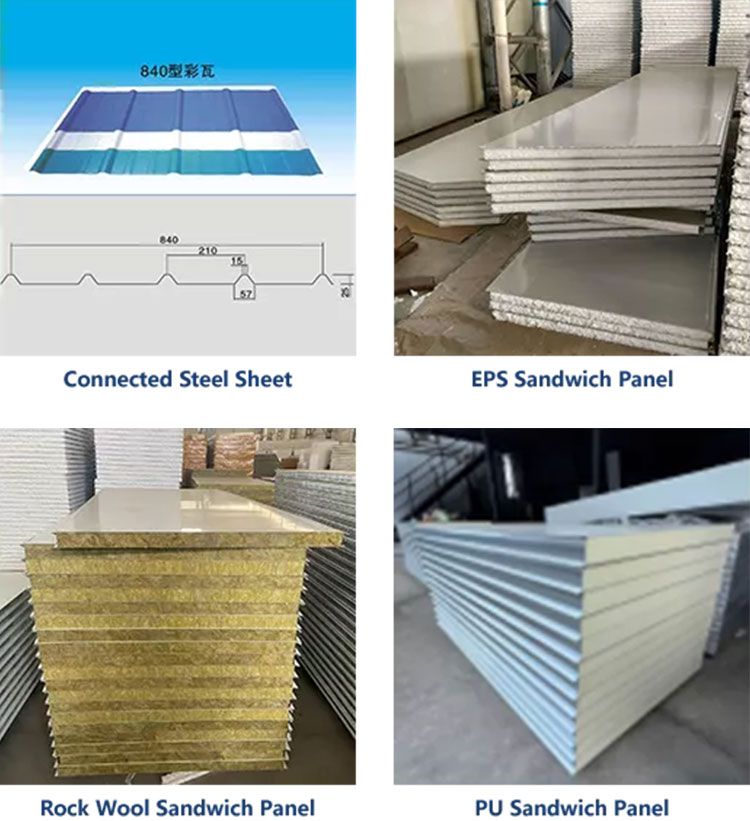

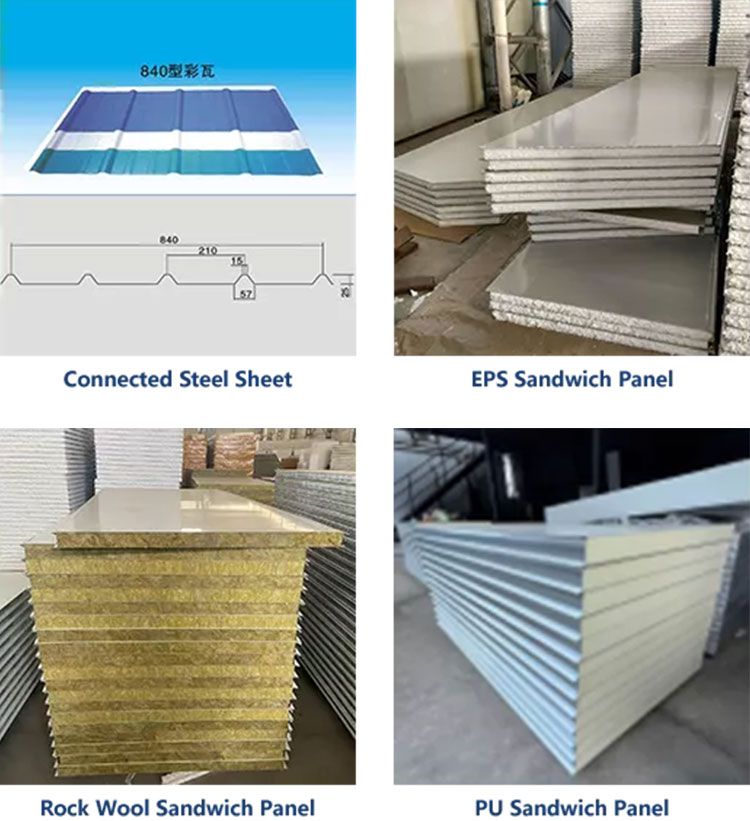

| Cladding Materials | Single Corrugated Steel Sheet, Sandwich Panels | Structure Surface Treatment | Any Color Painting or Hot Galvanize |

| Origin | Foshan, China | Specification | Customized Size |

| Production Capacity | 2000 Tons Per Month | Residential Wall Structure | Sandwich Panels |

| Connection Form | Bolt Connection | Customized | Customized |

| Type of Steel For Building Structure | H Beam Steel | HS Code | 9406000090 |

40 by 40 Metal Building

Steel structure workshops and warehouses are robust industrial buildings constructed primarily using steel. Known for their strength and flexibility, these structures offer versatile spaces for manufacturing, storage, and commercial operations. Utilizing steel columns, beams, and panels, they provide durable, customizable, and cost-effective solutions for various industries.

The advantages of steel structure workshops and warehouses include:

Strength and Durability: Steel’s robustness offers superior strength, enabling these structures to withstand heavy loads and adverse weather conditions.

Versatility in Design: Steel allows for flexible and customizable layouts, accommodating specific operational needs efficiently.

Cost Efficiency: Quick construction times and lower maintenance costs make steel structures a cost-effective choice in the long term.

Quick Construction: Compared to traditional building methods, steel structures can be erected relatively swiftly, reducing construction time and associated expenses.

Adaptability: Steel structures can be modified or expanded easily, allowing for future adjustments based on changing requirements.

Safety and Security: Steel provides excellent fire resistance and structural integrity, ensuring a safe environment for employees and assets.

Specifications

Components

A steel structure workshop or warehouse comprises several key components that work together to create a robust and functional space.Here are the primary components:

1. Primary Structural Elements

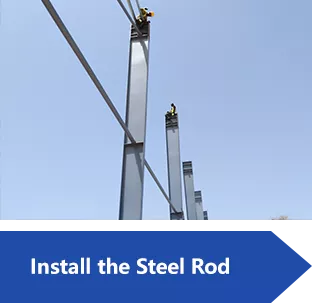

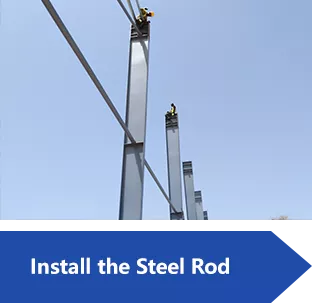

Columns: Vertical members that bear the load and provide support to the entire structure.

Beams: Horizontal members that connect columns, supporting the roof and transferring loads to the columns.

Frames: Combinations of columns and beams forming the basic skeleton of the structure.

2. Secondary Structural Elements

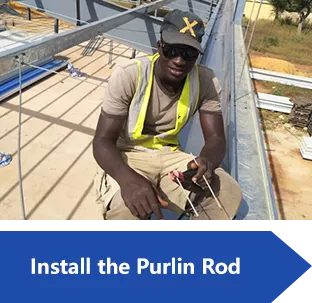

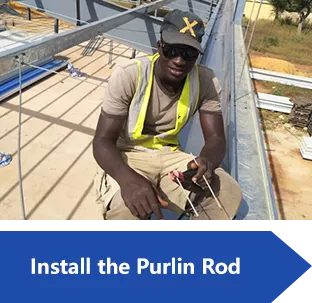

Purlins and Girts: Secondary horizontal members that support the roof and wall cladding.

Bracing: Diagonal or cross members that provide lateral stability to the structure against wind and other forces.

Ties and Struts: Additional elements to enhance structural integrity and load distribution.

3. Roofing and Cladding

Roof Panels: Steel sheets or panels that form the upper covering of the structure, providing weather protection.

Wall Cladding: Similar steel sheets or panels used to enclose the sides of the building, offering insulation and security.

4. Foundations

Footings: Provide support and distribute the weight of the structure to the ground.

Concrete Slabs or Flooring: Foundation for the workshop or warehouse, providing a sturdy base for operations.

5. Accessories and Additions

Doors and Windows: Installed within the structure to allow entry, natural light, and ventilation.

Mezzanine Floors: Intermediate floors between the main floors, increasing usable space for offices or storage.

Crane Systems: Overhead systems used for lifting and moving heavy equipment or materials.

6. Insulation and Coatings

Insulation Materials: Added to maintain internal temperatures and reduce energy costs.

Fireproofing and Protective Coatings: Applied for fire resistance and to prevent corrosion, extending the structure’s lifespan.

7. Utilities and Services

Electrical and Plumbing: Installed to accommodate lighting, machinery, and water supply as required by the workshop or warehouse operations.

Ventilation and HVAC Systems: Essential for air quality and maintaining comfortable working conditions.

Each component plays a crucial role in the overall functionality, stability, and efficiency of a steel structure workshop or warehouse. The integration and quality of these elements determine the longevity and suitability of the structure for its intended purpose.

Production Process

1.Steel Plate Flat Pressing

2.CNC Cutting

3.Assemble to H Steel

4.Submerged Arc Welding

5.Flaw Detection & Correction

6.Assembly with the Connection Plate

7.Welding

8.Grinding and Slag Removal

9.Quality Inspection Before Blasting

10.Shot Blasting for Rust Removal

11.Painting

12.Mark & Storage

Packing

and

Shipping

Packing and Shipping

Method 1: Open Top Cabinet

Method 2: Pack it with Racks and Put it Into 40HQ

Method 3: Bulk Loading Into 40HQ

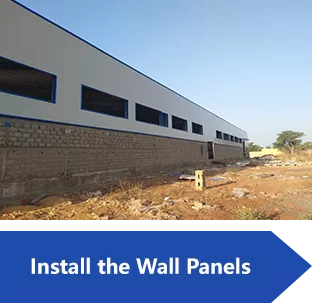

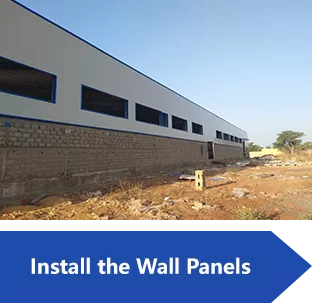

Installation Instruction

Design Softwares

Our Service

Professional design and engineering team

The full solution for house design. We could make the design for the whole house as per your requirement.

Procurement and Manufacture of all materials for prefabricated building

We have a professional procurement team to make sure all the materials are of good quality. Our factory operates under ISO standards, to make sure the fabrication works with high technology.

Site management & Installation supervision

We could send our engineers to help with the installation supervision, you just need to prepare a team that knows normal construction works will be OK.

FAQ

What is the lifespan of a steel structure workshop/warehouse?

Properly maintained steel structures can have a long lifespan, often exceeding several decades due to steel's durability and resistance to decay and pests.

What considerations should be made before constructing a steel structure workshop/warehouse?

Compliance with building codes, considering the intended use, required utilities, and safety measures like fire resistance and ventilation are vital considerations.

Are steel structure workshops/warehouses customizable?

Yes, these structures offer flexibility in design, allowing customization for layout, size, features, and even expansion or modifications as needed.

How are steel structure workshops/warehouses constructed?

Construction involves assembling steel columns, beams, and frames, adding steel roofing and wall cladding, and incorporating necessary features like doors, windows, and utilities.

What information do you need for a quote?

If you have drawings, please provide them along with material specifications. If not, share the intended usage and size requirements, and we'll design and offer you a competitive price accordingly.

How is your after-sales service?

Our support is available 24/7. We assign a dedicated person to oversee your order every step of the way. For installation, we provide 3D installation drawings. If needed, we can arrange an engineer to guide your workers, with expenses for double tickets, accommodation, food, and salary covered by you.

What products do you offer?

We specialize in steel structure warehouse & workshop, multi-storey structure building, steel structure garage, steel structure hangar, prefab labor camp, steel structure farm house, container house, and more.

Are you a factory or a trading company?

We're a factory located in Foshan City.

Project in Philippines

Project in SriLanka

Project in Angola

Project in Philippines T House

Project in Ghana

Project in Malaysia

Project in Senegal

Project in China

Project in Solomon

Project in Hong Kong

Project in Cameroon

Project in Australia

Project in New Guinea

Project in Cameroon

Project in Algeria