Steel structure platforms, also known as mezzanines, are a powerful solution for businesses looking to optimize space, enhance operations, and create additional work or storage areas. Whether you’re in manufacturing, warehousing, or retail, these platforms can transform underutilized vertical space into functional, safe, and efficient areas. However, designing and installing a steel structure platform requires careful planning and consideration to ensure it meets your specific needs and complies with safety standards.

This guide walks you through the key steps involved in designing and installing steel structure platforms, helping you make informed decisions that will maximize the benefits of your investment.

1. Assessing Your Needs and Objectives

Before diving into the design phase, it’s crucial to thoroughly assess your needs and objectives. Consider the following questions:

- Purpose: What will the platform be used for? (e.g., storage, office space, production lines)

- Load Requirements: How much weight will the platform need to support? (This includes equipment, inventory, and personnel)

- Space: How much space is available, and how do you plan to utilize it?

- Accessibility: How will workers access the platform? (e.g., stairs, ladders, lifts)

- Safety: What safety features are necessary, such as guardrails, non-slip surfaces, or fire resistance?

By clearly defining your requirements, you can ensure that the platform is tailored to your specific needs.

2. Design Considerations

Once you’ve assessed your needs, the design phase begins. Here are key factors to consider:

a. Structural Integrity and Load Capacity

The platform’s design must prioritize structural integrity, ensuring it can safely support the intended load. This involves calculating the load-bearing capacity based on the weight of stored items, equipment, and personnel. It’s essential to consult with structural engineers or experienced designers to ensure the platform meets or exceeds the required safety standards.

b. Material Selection

While steel is the primary material, different grades and types of steel may be used depending on the platform’s purpose and environment. For example, galvanized steel might be chosen for its corrosion resistance in humid environments, while hot-rolled steel might be used for heavy-duty applications.

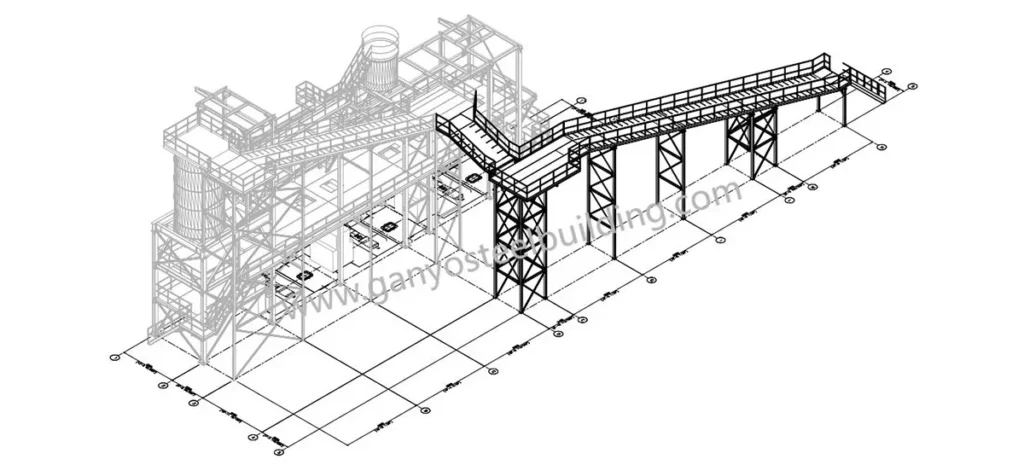

c. Layout and Configuration

The layout of the platform should be designed to optimize space utilization while maintaining easy access and workflow efficiency. Consider whether a single-level or multi-level platform best suits your needs. Additionally, the design should account for the placement of stairs, handrails, safety gates, and other access points.

d. Compliance with Regulations

Ensure that your design complies with all relevant local building codes, industry standards, and safety regulations. This may include guidelines from bodies such as OSHA (Occupational Safety and Health Administration) in the United States or equivalent organizations in other regions.

3. Installation Process

The installation of a steel structure platform is a critical phase that requires careful planning and execution to minimize disruption and ensure safety.

a. Site Preparation

Before installation begins, the site must be prepared. This includes clearing the area of any obstructions, marking out the installation area, and ensuring the ground or floor can support the platform’s weight. If necessary, reinforce the foundation to handle the additional load.

b. Prefabrication

Steel platforms are often prefabricated off-site to reduce installation time and costs. Prefabrication involves manufacturing components according to the design specifications, ensuring they fit together seamlessly during assembly.

c. Assembly and Erection

Once on-site, the prefabricated components are assembled and erected. This process should be carried out by experienced professionals, using appropriate lifting equipment and following safety protocols. The assembly typically begins with erecting the support columns, followed by the installation of beams, flooring, and access points.

d. Quality Control and Inspection

After assembly, the platform must undergo rigorous quality control checks and inspections to ensure it meets safety and structural standards. This includes checking load-bearing capacity, stability, and the integrity of welds and connections.

4. Post-Installation Considerations

After the platform is installed, there are several post-installation considerations to ensure it continues to perform optimally:

a. Maintenance and Inspection

Regular maintenance and inspections are essential to ensure the platform remains safe and functional. This includes checking for signs of wear and tear, corrosion, or damage and addressing any issues promptly.

b. Training and Safety Protocols

Ensure that all personnel who will use the platform are trained in its proper use and aware of the safety protocols. This includes understanding load limits, safe access methods, and emergency procedures.

c. Future Modifications

Steel structure platforms are often designed with flexibility in mind, allowing for future modifications or expansions. If your business grows or your needs change, consider whether the platform can be easily adapted to meet new requirements.

Conclusion

Designing and installing a steel structure platform is a significant investment that can offer substantial returns in terms of space optimization, efficiency, and safety. By carefully assessing your needs, working with experienced professionals, and following best practices throughout the design and installation process, you can ensure your platform meets your objectives and provides long-term value.

For expert guidance and high-quality steel structure platforms tailored to your business needs, contact Ganyo Steel Structure today at lizzy@ganyosteelbuilding.com.